RCMA

RCMA

At SILS Enterprise, we offer comprehensive Reliability-Centered Maintenance Analysis (RCMA) services to ensure your systems and equipment operate at peak efficiency. Our RCMA solutions help you develop maintenance strategies that optimize reliability, minimize downtime, and reduce overall maintenance costs.

What is RCMA?

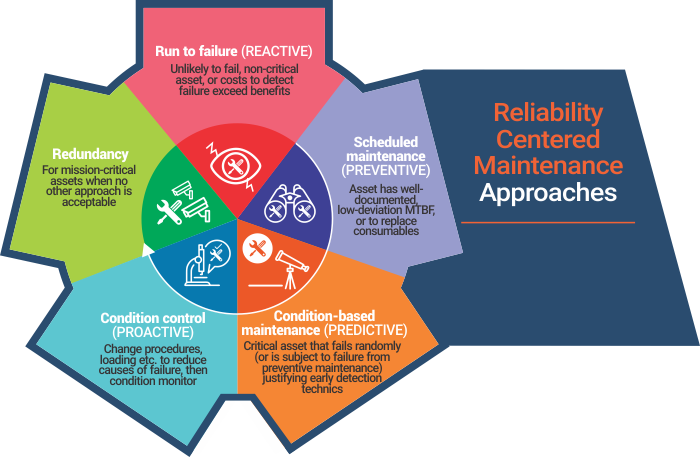

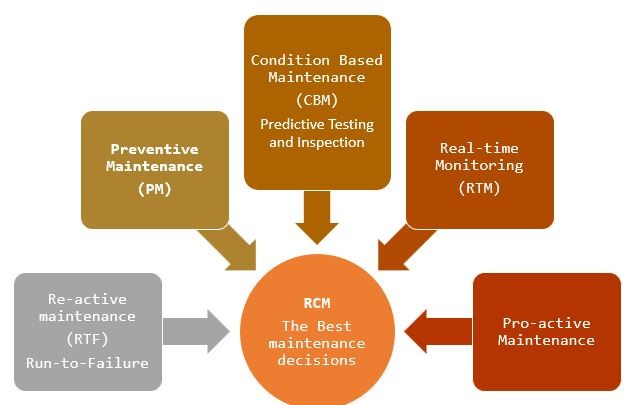

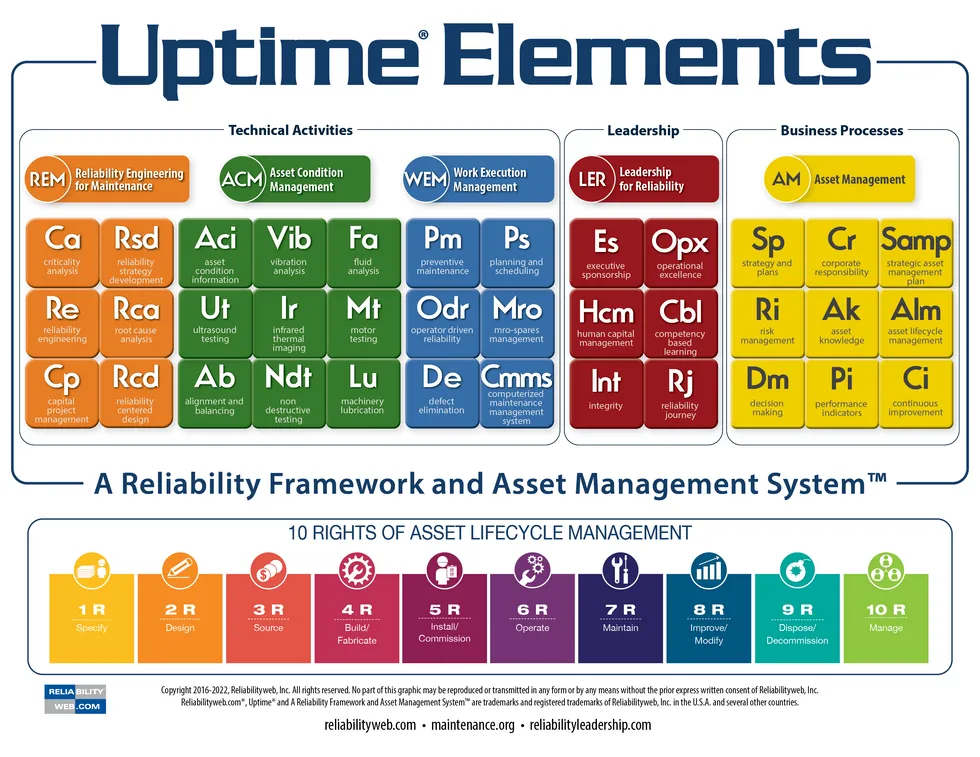

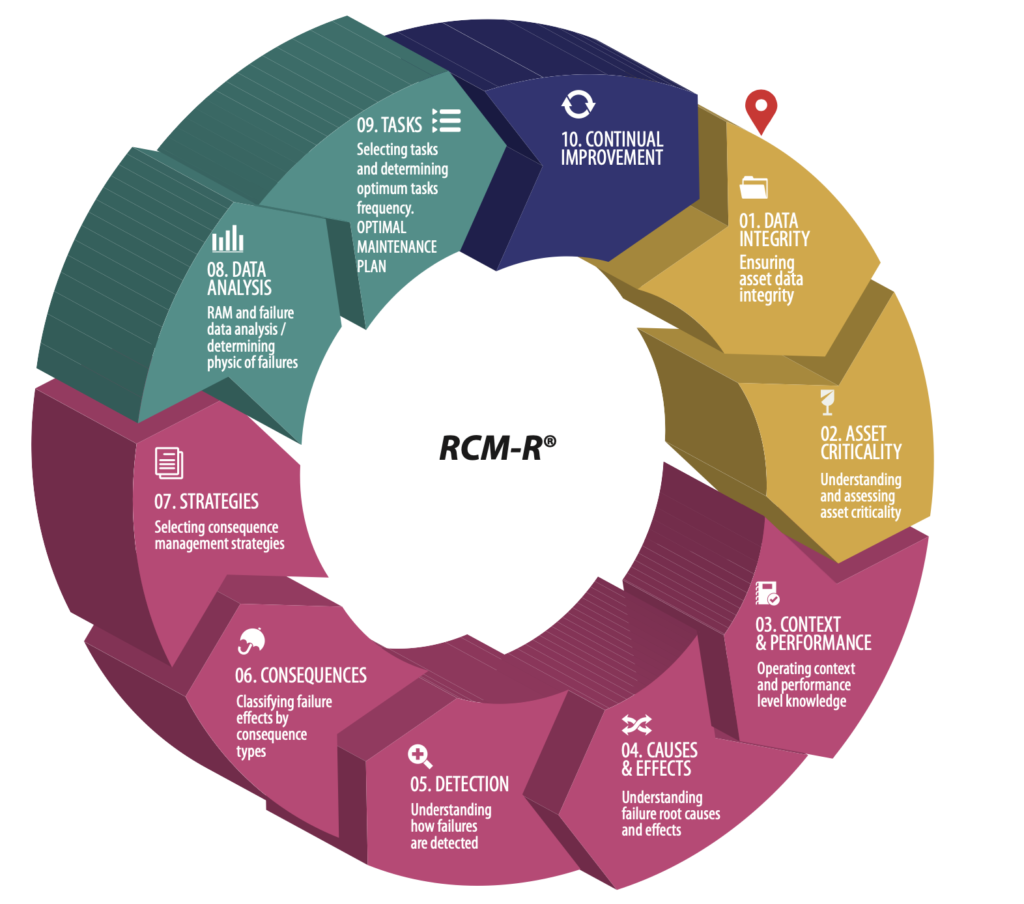

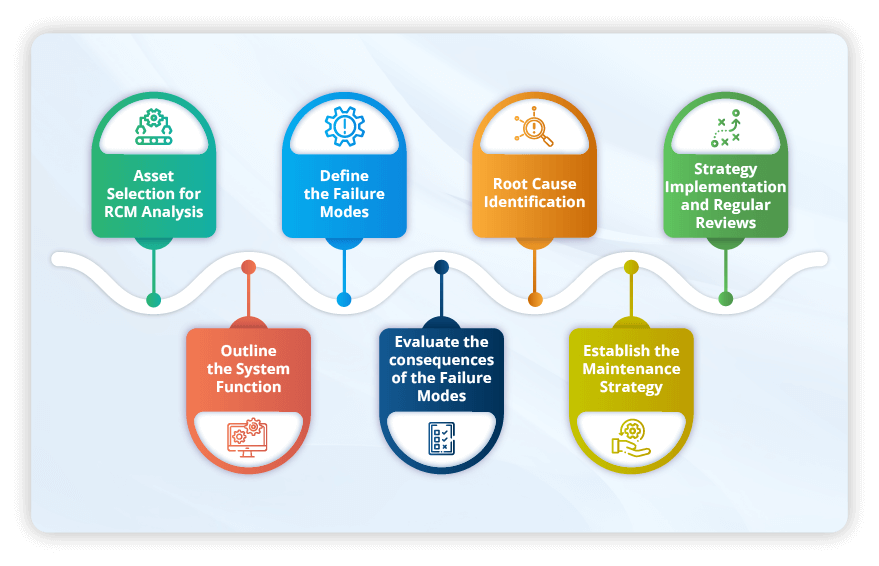

Reliability-Centered Maintenance Analysis (RCMA) is a structured process used to determine the maintenance strategies best suited to ensure the reliability and performance of systems and equipment. RCMA focuses on identifying potential failure modes, understanding their effects, and developing maintenance plans to prevent failures, extend equipment life, and optimize performance.

Why Choose RCMA?

Enhanced Reliability

Ensure systems and equipment operate reliably and efficiently.

Optimized Maintenance

Develop maintenance strategies that are effective and cost-efficient.

Reduced Downtime

Minimize unplanned downtime and increase operational availability.

Cost Savings

Reduce maintenance costs by implementing proactive and condition-based maintenance practices.

Our Services

RCM Analysis

We conduct detailed RCMA to identify critical components, potential failure modes, and their effects on system performance. Our services include:

- Functional Failure Analysis

- Failure Mode and Effects Analysis (FMEA)

- Criticality Analysis

Maintenance Strategy Development

We develop tailored maintenance strategies based on RCMA findings to optimize reliability and performance. Key services include:

- Preventive Maintenance Planning

- Predictive Maintenance Programs

- Condition-Based Maintenance (CBM) Strategies

Implementation Support

We assist in the implementation of maintenance strategies, ensuring they are effectively integrated into your operations. Services include:

- Maintenance Procedure Development

- Training and Support for Maintenance Personnel

- Integration with Maintenance Management Systems

Performance Monitoring and Optimization

We provide ongoing monitoring and optimization of maintenance strategies to ensure continuous improvement. Key services include:

- Key Performance Indicator (KPI) Tracking

- Maintenance Effectiveness Reviews

- Continuous Improvement Programs

Documentation and Reporting

We offer comprehensive documentation and reporting to support transparency and traceability of RCMA processes. Services include:

- Detailed Analysis Reports

- Maintenance Plans and Schedules

- Regular Updates and Reviews

Standards We Follow

Our RCMA services adhere to recognized international standards

to ensure the highest quality and reliability:

to ensure the highest quality and reliability:

SAE JA1011

Evaluation Criteria for RCM Processes

SAE JA1012

A Guide to the Reliability-Centered Maintenance (RCM) Standard

ISO 55000

Asset Management – Overview, Principles, and Terminology

ISO 31000

Risk Management – Principles and Guidelines

IEC 60300-3-11

Dependability Management – Application Guide – Reliability-Centered Maintenance

MIL-STD-2173

Reliability-Centered Maintenance Requirements for Naval Aircraft, Weapons Systems, and Support Equipment

DEF STAN 02-45

Requirements for RCM in Ship Design

Benefits of Our RCMA Services

Increased Reliability

Identify and mitigate potential failure modes to enhance system reliability.

Cost Efficiency

Implement effective maintenance strategies that reduce overall maintenance costs.

Improved Safety

Proactive maintenance strategies ensure safer operating conditions.

Operational Excellence

Optimize maintenance practices to improve overall operational performance.

Industries We Serve

Our RCMA services are applicable across various industries, including:

Aerospace & Defense

Enhance the reliability and availability of critical systems.

Automotive

Optimize maintenance for vehicles and manufacturing equipment.

Healthcare

Ensure the reliability and safety of medical devices and equipment.

Manufacturing

Improve the reliability and efficiency of production systems.

Energy

Maximize the reliability and performance of energy production and distribution systems.