FMEA and FMECA Services

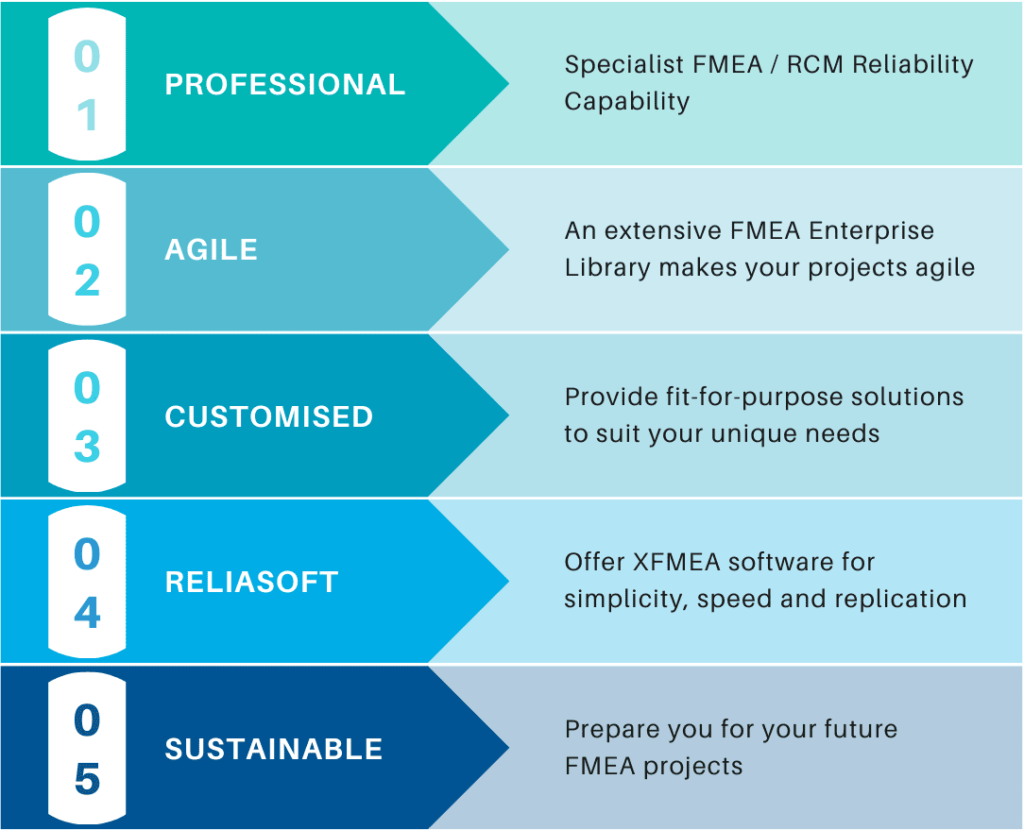

At SILS Enterprise, we provide comprehensive Failure Mode and Effects Analysis (FMEA) and Failure Mode, Effects, and Criticality Analysis (FMECA) services. Our expertise ensures your products and systems are reliable, safe, and meet the highest standards of quality.

FMEA/FMECA

What is FMEA?

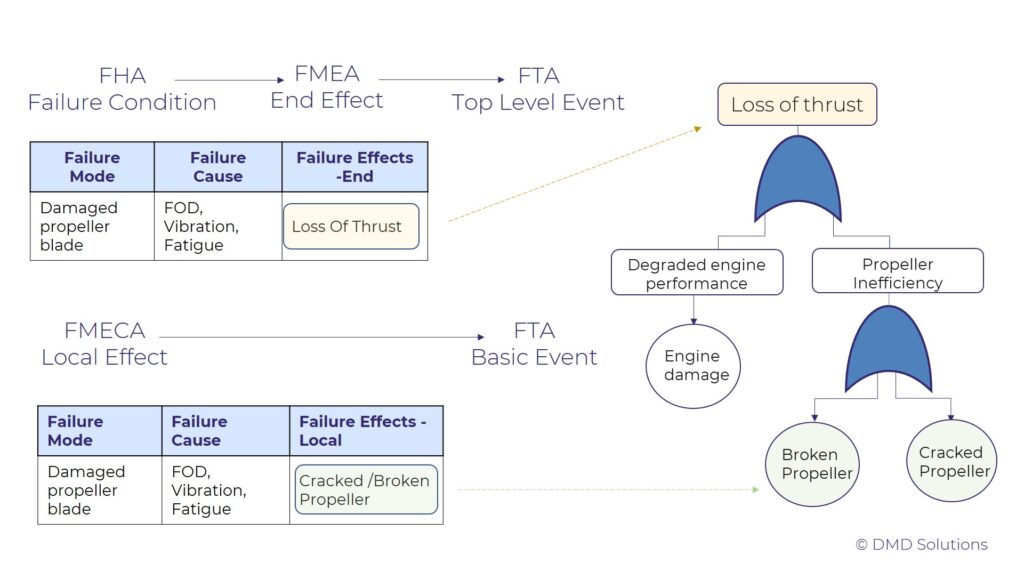

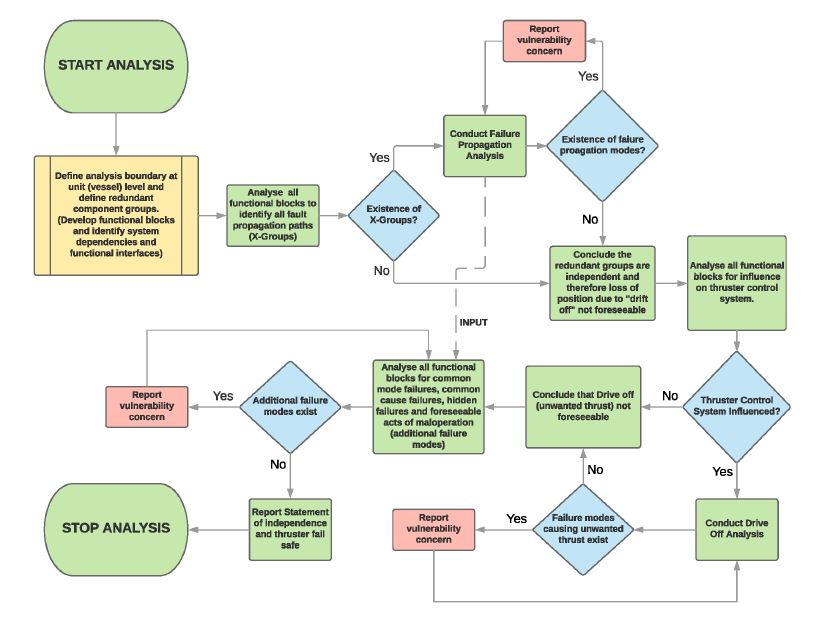

Failure Mode and Effects Analysis (FMEA) is a systematic method for identifying potential failure modes in a product or process and analyzing the effects of these failures. FMEA helps prioritize risks and implement corrective actions to improve reliability and prevent failures.

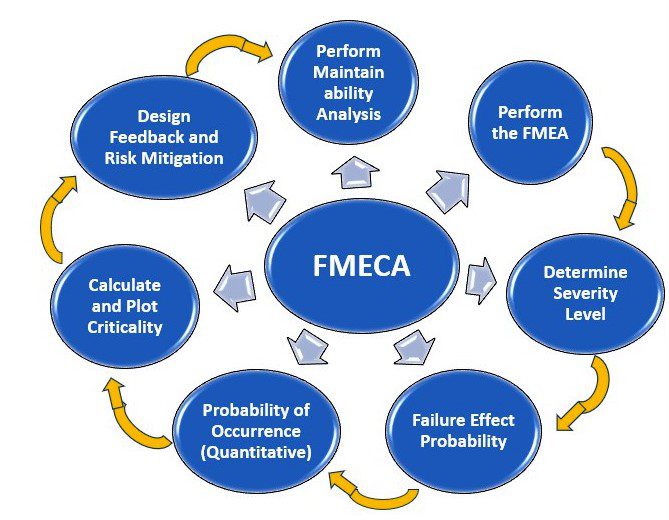

What is FMECA?

Failure Mode, Effects, and Criticality Analysis (FMECA) is an extension of FMEA that includes a criticality analysis. This analysis assesses the severity, occurrence, and detectability of potential failures, providing a more detailed evaluation of risk and guiding more focused mitigation efforts.

Why Choose FMEA and FMECA?

Risk Mitigation

Identify and address potential failure modes before they occur, reducing the risk of failures.

Improved Reliability

Enhance the reliability and durability of your products by addressing weak points in design and process.

Cost Savings

Prevent costly recalls and repairs by identifying and mitigating risks early in the development process.

Regulatory Compliance

Meet industry standards and regulatory requirements for safety and quality.

Our Services

FMEA Development

We conduct thorough FMEA to identify potential failure modes and their effects on your products or processes. Our services include:

- Design FMEA (DFMEA)

- Process FMEA (PFMEA)

- System FMEA

FMECA Development

We extend the FMEA process to include criticality analysis, providing a more detailed risk assessment. Services include:

- Criticality Assessment

- Severity, Occurrence, and Detectability Analysis

- Risk Priority Number (RPN) Calculation

Corrective Action Planning

We develop and implement corrective action plans based on FMEA and FMECA findings to mitigate identified risks. Key services include:

- Action Plan Development

- Implementation Support

- Effectiveness Verification

Training and Workshops

We offer training programs and workshops to help your team understand and apply FMEA and FMECA methodologies effectively. Services include:

- Customized Training Programs

- Hands-On Workshops

- Ongoing Support and Coaching

Documentation and Reporting

We provide detailed documentation and reporting to ensure transparency and traceability of the FMEA and FMECA processes. Key services include:

- Comprehensive Reports

- Documentation of Findings and Actions

- Regular Updates and Reviews

Standards We Follow

Our FMEA and FMECA services adhere to recognized international

standards to ensure the highest quality and reliability:

standards to ensure the highest quality and reliability:

ISO 9001

Quality management systems

ISO 31000

Risk management – Principles and guidelines

IEC 60812

Analysis techniques for system reliability – Procedure for failure mode and effects analysis (FMEA)

SAE J1739

Potential Failure Mode and Effects Analysis in Design (Design FMEA), Potential Failure Mode and Effects Analysis in Manufacturing and Assembly Processes (Process FMEA)

MIL-STD-1629A

Procedures for Performing a Failure Mode, Effects, and Criticality Analysis

Benefits of Our FMEA and FMECA Services

Enhanced Product Quality

Systematic analysis and mitigation of potential failures lead to higher product quality.

Increased Customer Satisfaction

Reliable and safe products result in higher customer satisfaction and loyalty.

Regulatory Compliance

Ensure compliance with industry standards and regulatory requirements.

Informed Decision-Making

Detailed risk assessments provide valuable insights for informed decision-making.

Industries We Serve

Our FMEA and FMECA services are applicable across various industries, including:

Aerospace & Defense

Ensure the reliability and safety of critical systems.

Automotive

Improve vehicle safety and performance through comprehensive risk analysis.

Healthcare

Enhance the safety and reliability of medical devices and equipment.

Manufacturing

Optimize processes and prevent failures in production systems.

Energy

Ensure the reliability and safety of energy production and distribution systems.